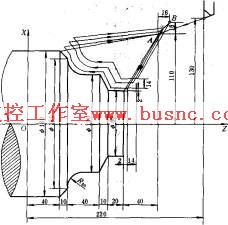

用G73粗车循环的例子

设粗加工分三刀进行,第一刀后留给剩下两刀的总余量X向和Z向均为单边14mm三刀完毕,留给精加工的余量X方向(直径上)为4.0mm;Z向为2.0mm粗加工进给量为0.3mm/r主轴转速为500r/min精加工进给量为0.15mm/r主轴转速为800r/min完成上述加工的程序如下:

%0004

N01

G92

X260.0 Z220.0

N02 G00

X220.0 Z160.0

M03 S800

G95 F0.30

(转进给)

N03 G73

U14.0

K14.0

R3 P04 Q09 G91 X4.0 Z2.0 F0.30 S500

N04 G00

X80.0 W-40.0

N05 G01

W-20.0 F0.15 S800

N06 X120.0

W-10.0

N07 W-20.0

N08 G02

X160.0 W-20.0 I20.0

N09 G01

X180.0 W-10.0

N10 G94

F1000

N11 G01

X260.0 Z220.0

N12 M05

N13 M30