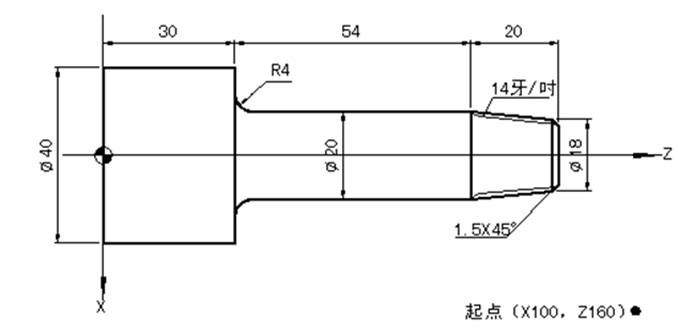

编程举例.图示如下零件

材料:45#,

毛坯:锻件,

单边余量约1mm,

螺纹为英制锥螺纹,螺距每英寸14牙,

1#刀:外圆刀,

2#刀:外螺纹刀

刀具起始点为(X100,Z160)

N0010 M03 S1000

N0020 M08

N0030 G00 X100 Z160

N0040 T1

N0050 G00 X44

Z30.2 (快速进刀)

N0060 G01 X30

F120 (粗车端面)

N0070 G00

Z107 (快速退刀)

N0080 G00

X18.4 (快速进刀)

N0090 G01 Z104

F120 (慢速进刀)

N0100 G01 X20.4

Z84 (粗车外锥,

直径余量0.4)

N0110 G01

Z34 (粗车外圆φ20)

N0120 G02 X28 Z30.2 R3.8

F80 (粗车R4)

N0130 G01 X40.2

F120 (粗车端面)

N0140 G01

Z10 (粗车外圆φ40)

N0150 G00

Z104 (快速退刀)

N0160 S1500

N0170 G00

X24 (快速进刀)

N0180 G01 X10

F120 (精车端面)

N0190 G01 X15

N0200 G01 X18

Z102.5 (倒角1.5×45)

N0210 G01 X20

Z84 (精车锥度)

N0220 G01 Z34

(精车外圆φ20)

N0230 G02 X28 Z30 R4

F80 (精车R4)

N0240 G01 X40

F120 (精车端面)

N0250 G01

Z10 (精车外圆φ40)

N0260 G00 X100

Z160 (快速退刀)

N0270

T2 (换螺纹刀加工螺纹)

N0280 S700

N0290 G00 X17.8

Z106 (快速进刀)

N0300 G87 X20 Z84 K14 I4

R1.96 L8 (车削锥度螺纹)

N0310 G00 X100 Z160

N0320 M05

N0330 M09

N0340 T1

N0350 G00 X100 Z160

N0360 M02